Wire

Tag Marker

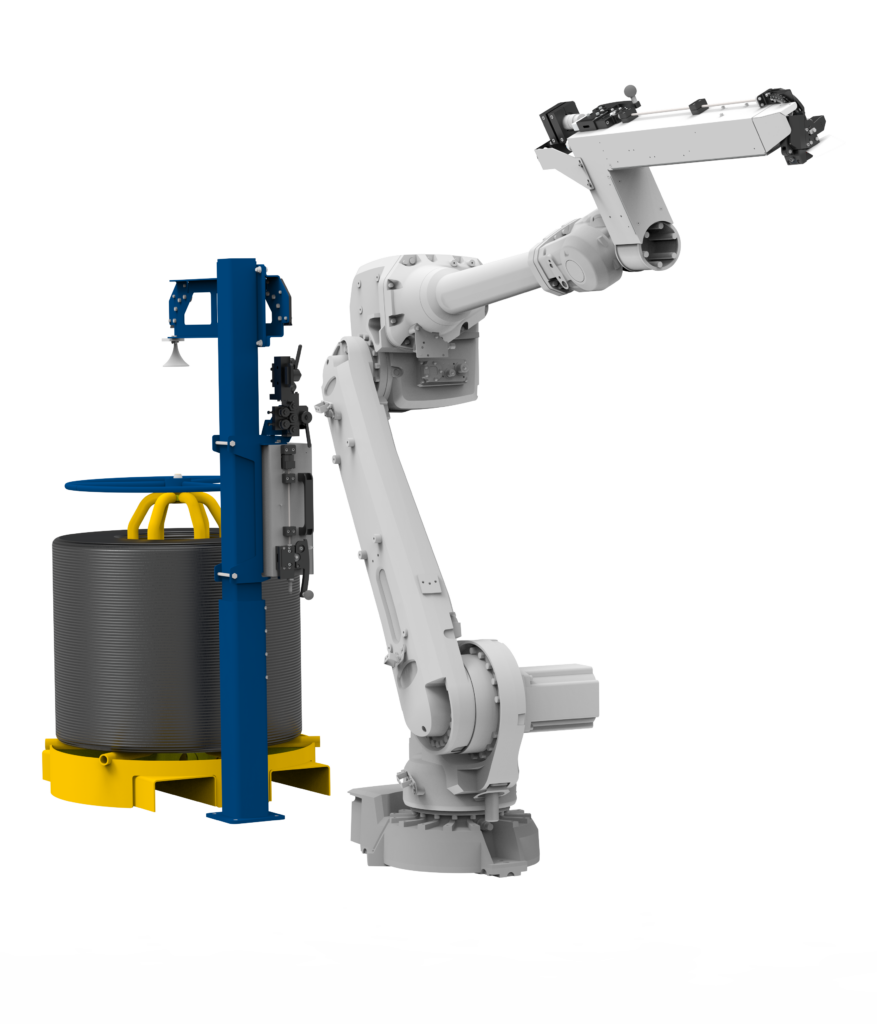

Automatic Labelling Station

The Automatic Labelling Station is designed with focus on high availability, high accuracy and low service level. The system assures a high consistent quality.

Automatic labelling with instant quality control

This system is responsible of tagging wire rod coils and a quality system. The level of quality parameters is optional by client and the quality data can be stored for track history.

Operation

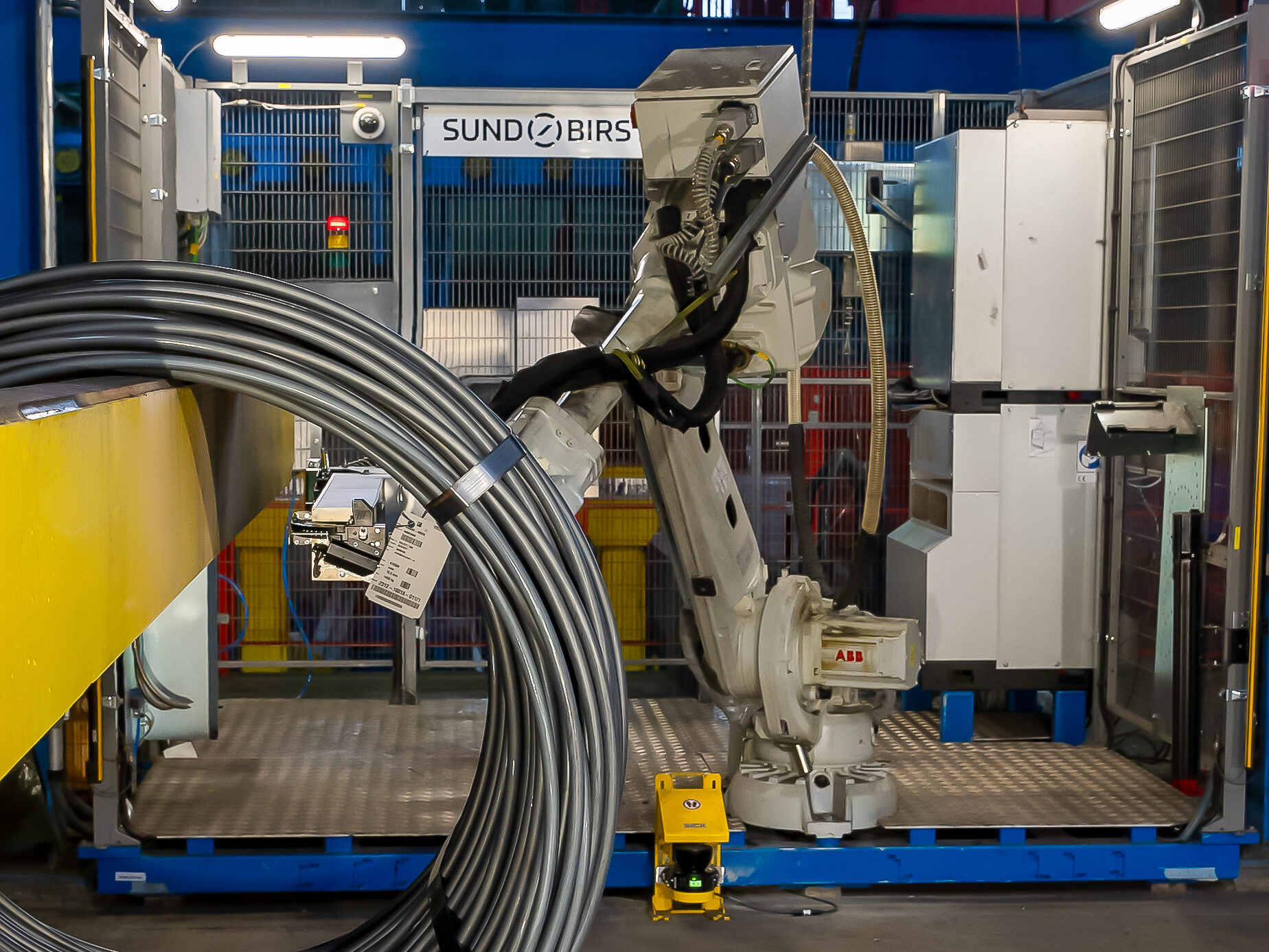

The Automatic Labelling Station consists of a integrated coil inspection system. The camera system creates a 3D point cloud which is used as a quality control and verification that the coil is up to accepted level to be tagged.

The 3D scanning with the robot detects all possible positions for tagging. The fastest and most available positions is chosen by the system. Within 2 seconds the applicator unit creates a wire loop that applies to tag the coil. After the tag is attached to the coil the system verifies that the tag has been attached to the coil. As an option the verified data can be stored in an OPC server as a quality assurance.

Self-contained unit

The Automatic Labelling Station is a self-contained unit, which can be an option for new handling systems or installed in existing equipment.

High availability

The high availability of Sund Birsta machines increases productivity and reduces cost.

Easy installation

The Automatic Labelling System is designed to easily integrate both in new equipment or in existing equipment as an upgrade.

Fits into existing plants

The Automatic Labelling Station is a perfect fit, both in new applications and in existing plants.

Low maintenance

As the system is delivered with a complete service package, wear parts, spare parts, service and design updates are included. This sets a low cost of ownership and assure a high accuracy for the function.

Robust design

Like all machines and handling systems from Sund Birsta, the Automatic Labelling Station is reliable and durable.

Applicator unit

The applicator unit is designed for quick change and the strong design makes it reliable. It has it’s own cooling system, and sensitive equipment such as camera system are well protected.

The applicator unit is a part of Sund Birsta’s exchange service system for making sure to achive highest availability. This for avoiding non-planned stop and reduce number of service activities.

| Technical Specification | Automatic Labelling Station |

|---|---|

| Binding wire (mm) | 1,8 |

| Loop diamater (mm) | 55-67 |

| Binding time (s) | 2-4 |

| Net weight (kg) | 1000-1500 |

Operation

The Automatic Labelling Station consists of a integrated coil inspection system. The camera system creates a 3D point cloud which is used as a quality control and verification that the coil is up to accepted level to be tagged.

The 3D scanning with the robot detects all possible positions for tagging. The fastest and most available positions is chosen by the system. Within 2 seconds the applicator unit creates a wire loop that applies to tag the coil. After the tag is attached to the coil the system verifies that the tag has been attached to the coil. As an option the verified data can be stored in an OPC server as a quality assurance.