Bar & Section

Bar Handling System

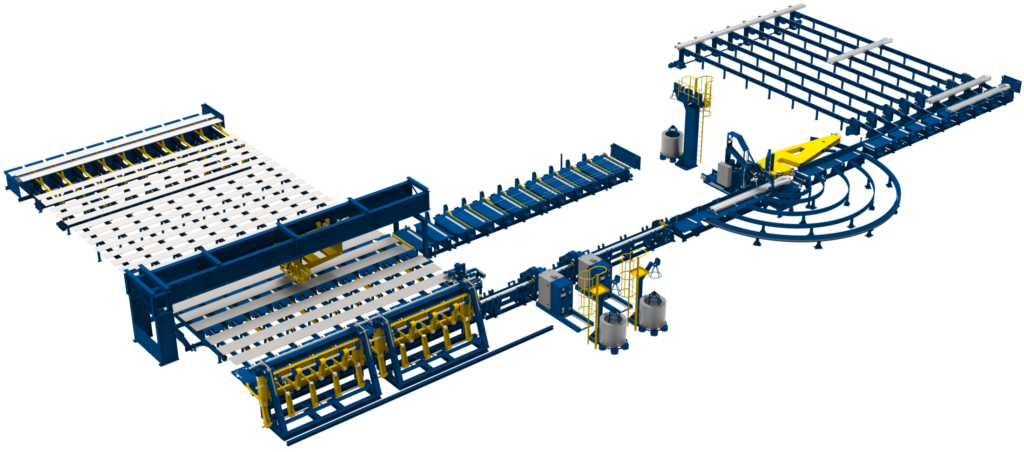

The Sund Birsta bar handling system is designed for smooth and gentle handling of bars and bundles. The bar handling system can be configured for both sub bundles and master bundles, or a combination of both.

A versatile bar handling system

The bar handling system is designed to fit the mill layout based on capacity, number of workstations, bar and bundle weight, and buffer requirements.

A high-quality and cost-efficient bar handling system

The bar handling system has a modern, space-saving design using very little floor space, and has buffer areas to enable efficient operation, providing high capacity through the system. The system uses frequency drives for optimized positioning and speed control with minimum power consumption.

The system operates fully automatically but individual sections can also be operated manually.

Optimized Safety System

Safety is an important issue for Sund Birsta. Our machines and handling equipment are designed to meet high demands on macine safety. Depending on your requirements, we offer an optimized safety system.

Electrical Control System – Tracking

The complete handling system, from exiting the cold shear to unloading of formed and tied or strapped bundle, is fully automatic PLC controlled. Tracking of the sheets and bundles is based on the mill computer system.

Bar Handling System

Upgrades

Automatic Labelling Station

Designed for high availability, great accuracy and low maintenance, the automatic labelling station assures a consistent high quality. It has an integrated bundle inspection system, with a camera that scans possible positions for tagging and chooses the best one for tagging of the bundle end.

Workshop Service

Each machine has its own unique service demands, and we also understand that each of our customers have their own individual requirements. Our service reflect that, and we deliver the best maintenance available for your Sund Birsta system. Contact us with your specific service and inspection needs.