Bar & Section

Binding Machine

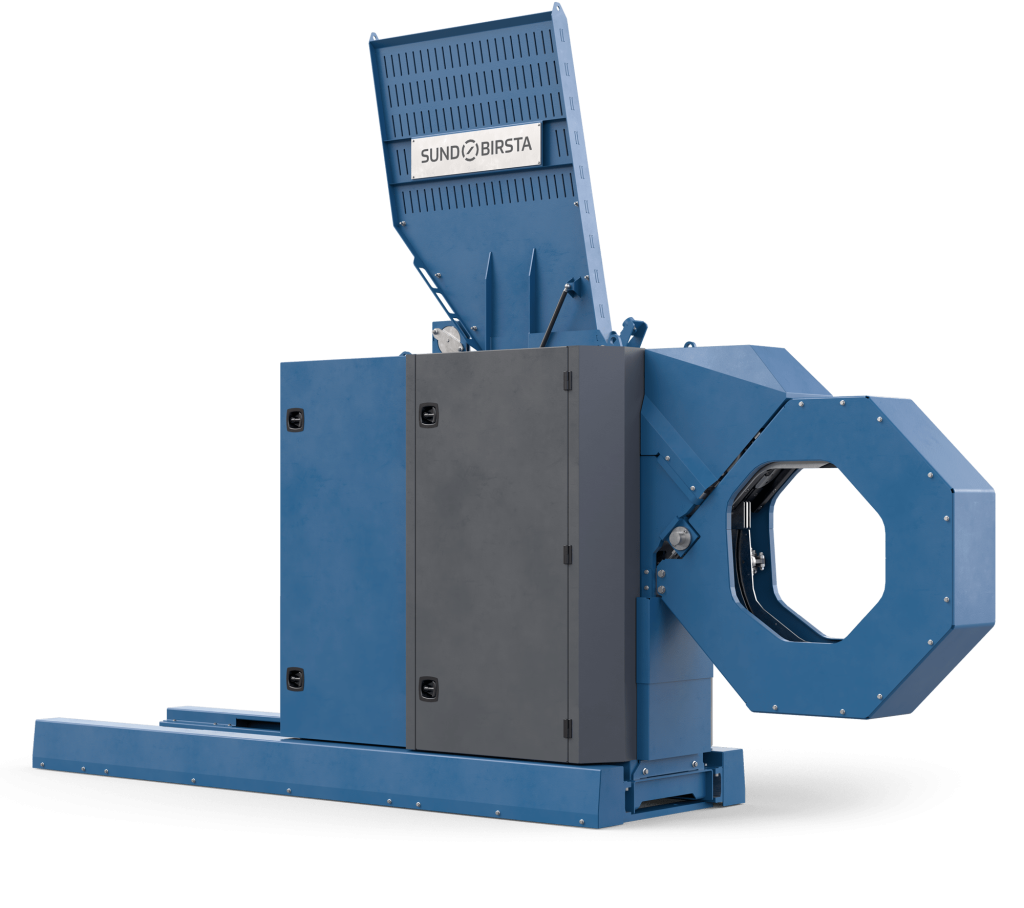

KN Delta

The KN Delta Wire Binding Machine is designed for binding medium sized bundles of bars and sections. It is fast, reliable and durable.

Energy-efficient binding of medium bundles

Building on proven Sund Birsta technology, the KN Delta represents a new generation of wire binding machines, combining gear motors with a minimal hydraulic unit. This makes the machine low-maintenance and very energy-efficient.

Short cycle time

To achieve a high production rate, short cycle times are essential. The KN Delta completes a single loop in 5–6 seconds, and a double loop in 6.5–8 seconds.

Easy installation

The KN Delta is designed to easily integrate into any line in the rolling mill industry.

Variable binding wire width

The machine can use binding wire of different width (5.5–6.5 mm) without any modifications.

Long life span

The robust design of the KN Delta makes the machine reliable and durable.

Low maintenance

Few wear parts and easy access to service makes the KN Delta very low-maintenance.

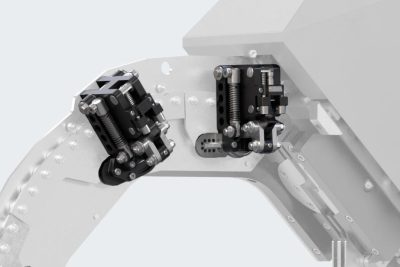

Few wear parts

The design of the KN Delta minimizes wear parts, making the machine low-maintenance.

Operations of KN Delta Binding Machine

The KN Delta Wire Binding Machine is designed for binding medium sized bundles

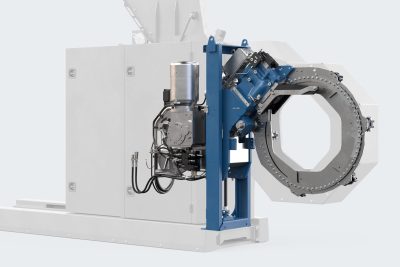

The combination of gear motors and a minimal hydraulic unit makes the machine highly energy-efficient. The hydraulics are only activated when needed, making the energy consumption in stand-by mode far lower compared to an exclusively hydraulic machine.

As a bundle arrives at the binding position, the binding wire is fed, tightened and tied extremely tight around the bundle. The cycle time is short and efficient, with high availability. Also, the KN Delta can perform both single and double bindings.

Extremely tight bindings

The wire stretching operation ties the knot extremely tight to the bundle.

Patented flap

Our patented, fully mechanical flap makes sure the wire is tight around the bundle, without hydraulics or an electric motor.

Interchangeable core technology

The binding unit can be lifted out for service, making it possible to minimize downtime by immediately putting in a replacement.

Easy service access

By adding an electric motor, the KN Delta can easily be moved to gain access for service.

Energy-efficient hydraulic operation

With its semi electric binding technology, the KN Delta has 70 percent lower energy consumtion compared to traditional hydraulic binding machines.

Conventional binding machine

KN Delta wire binding machine

| Technical specification | KN Delta |

|---|---|

| Length (mm) | 3162 |

| Width (mm) | 1000 |

| Height (mm) | 1890 |

| Binding wire (mm) | Ø 5.5-6.5 |

| Bundle size (mm) | Ø 150-350 |

| Binding time (s) | 5-8 |

| Net weight (kg) | 2200 |