Bar & Section

Bundle Former

KNOF

The KNOF Bundle Former is designed to form and tighten bundles of reinforced bars, or similar products. By compacting the bundles as tight as possible, the bar handling is made more cost-efficient throughout the production line.

Efficient and reliable forming of bundles

With its compact design and reliable performance, the KNOF is an essential part of any efficient rolling mill.

Tight bundles

The KNOF forms very tight, high-quality bundles of bars.

Compact design

The compact design of the KNOF makes it easy to fit into the production line.

Fully automatic operation

The machine is fully automatic, but can also be operated manually from a control panel.

Cost-efficient solution

The tighter the bundles, the more cost-efficient the mill.

Low maintenance

Few wear parts and easy access to service makes the KNOF very low-maintenance.

Robust design

Like all machines from Sund Birsta, the KNOF is durable with a long life-span.

Operations of KNOF Bundle former

Consisting of two hydraulic-powered arms, the KNOF Bundle Former normally operates together with a binding machine or a strapping machine. While the KNOF tightens and forms the bundle, the binding or strapping machine seals it.

The KNOF is fully automatic, but can also be operated manually from a control panel.

Guides

The guides for the bars can be customized to the specific angle that best suits your specific production line.

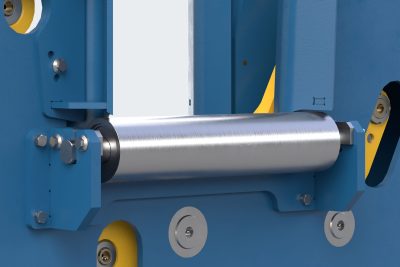

Guide rollers

We supply high-quality rollers for the KNOF, for guiding the bars into the machine.

| Technical specification | A/350 | A/400 | A/500 |

|---|---|---|---|

| Length (mm) | 1160 | 1560 | 1560 |

| Width (mm) | 310 | 310 | 310 |

| Height (mm) | 1240 | 1500 | 1500 |

| Bundle size (mm) | Ø 150-350 | Ø 135-400 | Ø 215-440 |

| Time for max. stroke (s) | >1,5 | >2 | >2 |

| Total weight (kg) | ~360 | ~500 | ~510 |

| Normal working pressure (bar) | 100 | 100 | 100 |

| Max. working pressure (bar) | 130 | 130 | 130 |

| Max. hydraulic flow (l/min) | 30 | 30 | 30 |