Bar & Section

Binding Machine

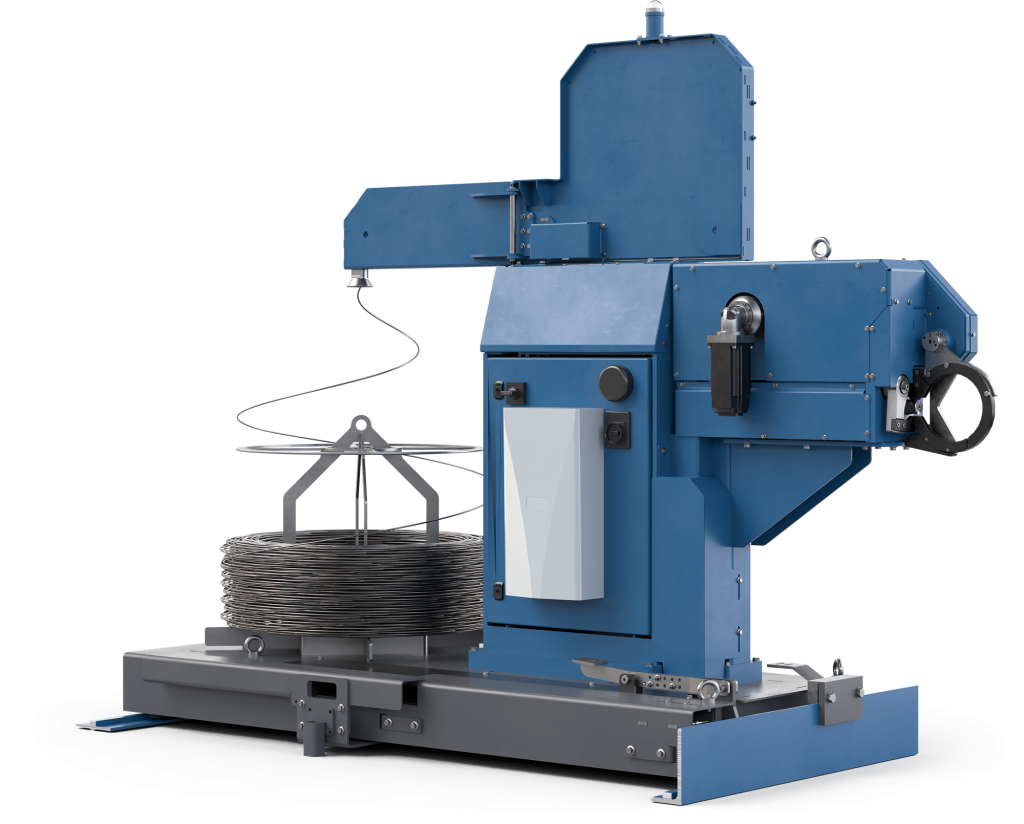

KNSe

The fully electrical KNSe Binding Machine is designed for binding small and medium-sized bundles of bars and sections, also referred to as sub bundles. It is reliabe, durable and very energy-efficient.

Energy-efficient binding of small bundles

Building on proven Sund Birsta technology, the KNSe offers a new human-machine interface (HMI), great serviceability and an interchangeable wire magazine for increased productivity.

Self-container unit

The KNSe is a self-contained unit, which simplifies installation and improves reliability.

High availability

The high availability of Sund Birsta machines increases productivity and reduces costs.

Easy installation

The KNSe is designed to easily integrate into any line in the rolling mill industry.

Fits into existing plants

The KNSe is a perfect fit, both in new applications and in existing plants.

Low maintenance

Few wear parts and easy access to service makes the KNSe very low maintenance

Robust design

Like all machines and handling systems from Sund Birsta, the KNSe is reliable and durable.

Operations of KNSe Binding Machine

The KNSe Binding Machine is designed for binding small and medium-sized bundles of bars and sections.

It is a self-contained unit, which simplifies installation and improves reliability. This makes the KNSe capable of meeting the requirements of most producers of small to medium-sized bundles, both in new applications and in existing plants.

When a bundle arrives at the binding position, the wire guide track closes around the bundle.

The binding wire is fed out of the wire magazine, and tightened around the bundle. The wire is cut when the twisting head starts to rotate to wind the ends together.

The machine is fully automatic, but can also be manually operated from a local control panel.

Human-Machine Interface (HMI)

The HMI of the KNSe lets the operator change the machine’s parameters. It also features service instructions, a guide for trouble solving and alerts for changing of wear parts.

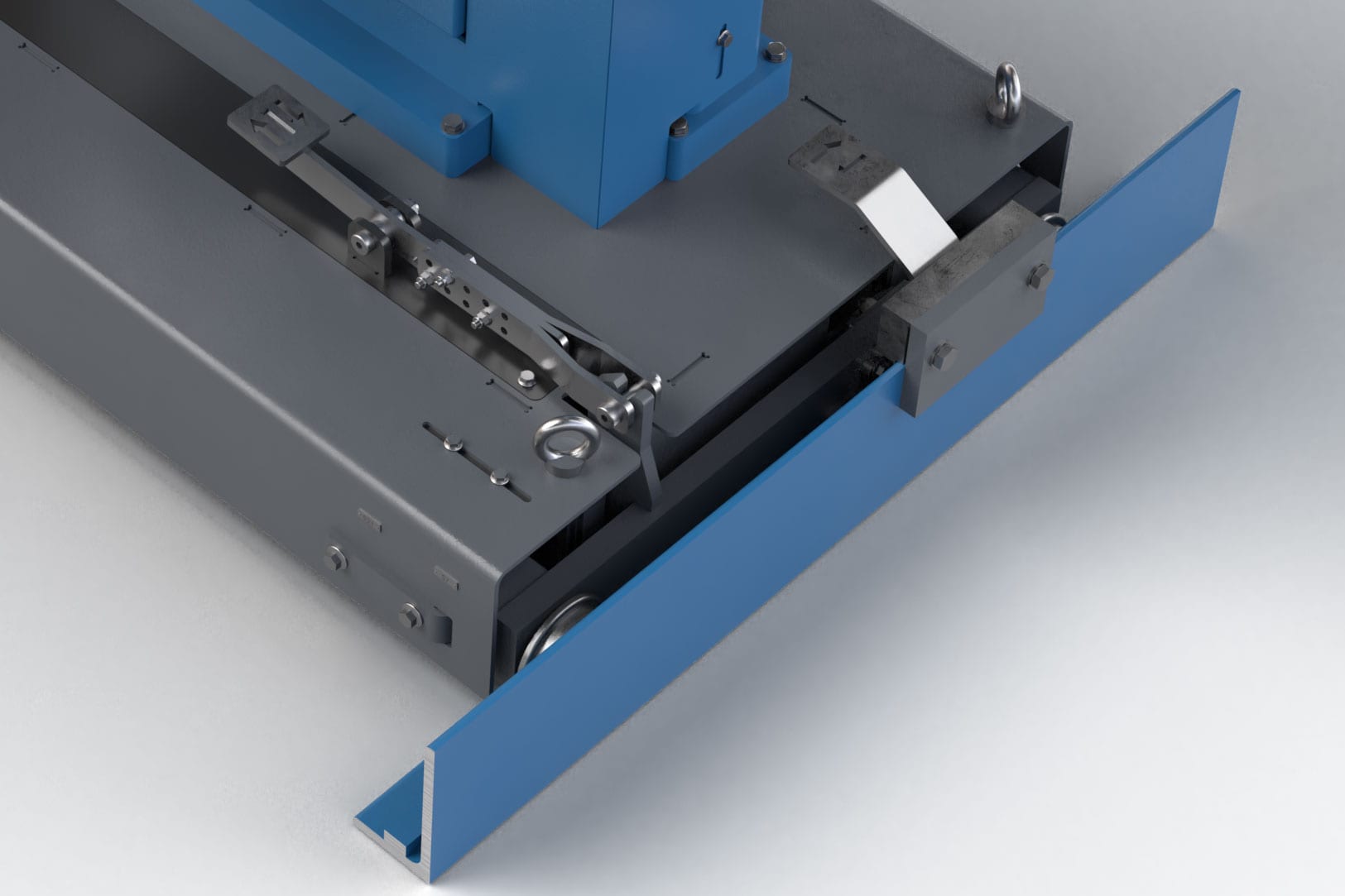

Pedals for easy access

The machine has two pedals, one for quick and easy access to service and one for hassle-free release from the production line, enabling fast shifting of binding position.

Larger wire magazine

You have the option to feed the KNSe from a separate, larger wire magazine. This lets the machine run continuously for up to four times longer, increasing productivity.

Interchangeable core technology

The binding unit can be lifted out for service, making it possible to minimize downtime by immediately putting in a replacement. It can also be fitted into legacy machines, with a retrofit package.

Energy-efficient electrical operation

With its fully electrical binding technology, the KNSe has 90 percent lower energy consumtion compared to traditional hydraulic machines.

Conventional hydraulic binding machine

KNSe Binding Machine

| Technical specification | KNSe |

|---|---|

| Length (mm) | 2100 |

| Width (mm) | 1230 |

| Height (mm) | 1400 |

| Binding wire (mm) | Ø 2.6-4.0 |

| Bundle size (mm) | Ø 40-120 / 40-250 |

| Binding time (s) | 2-4 |

| Net weight (kg) | 1 000-1 500 |