Wire

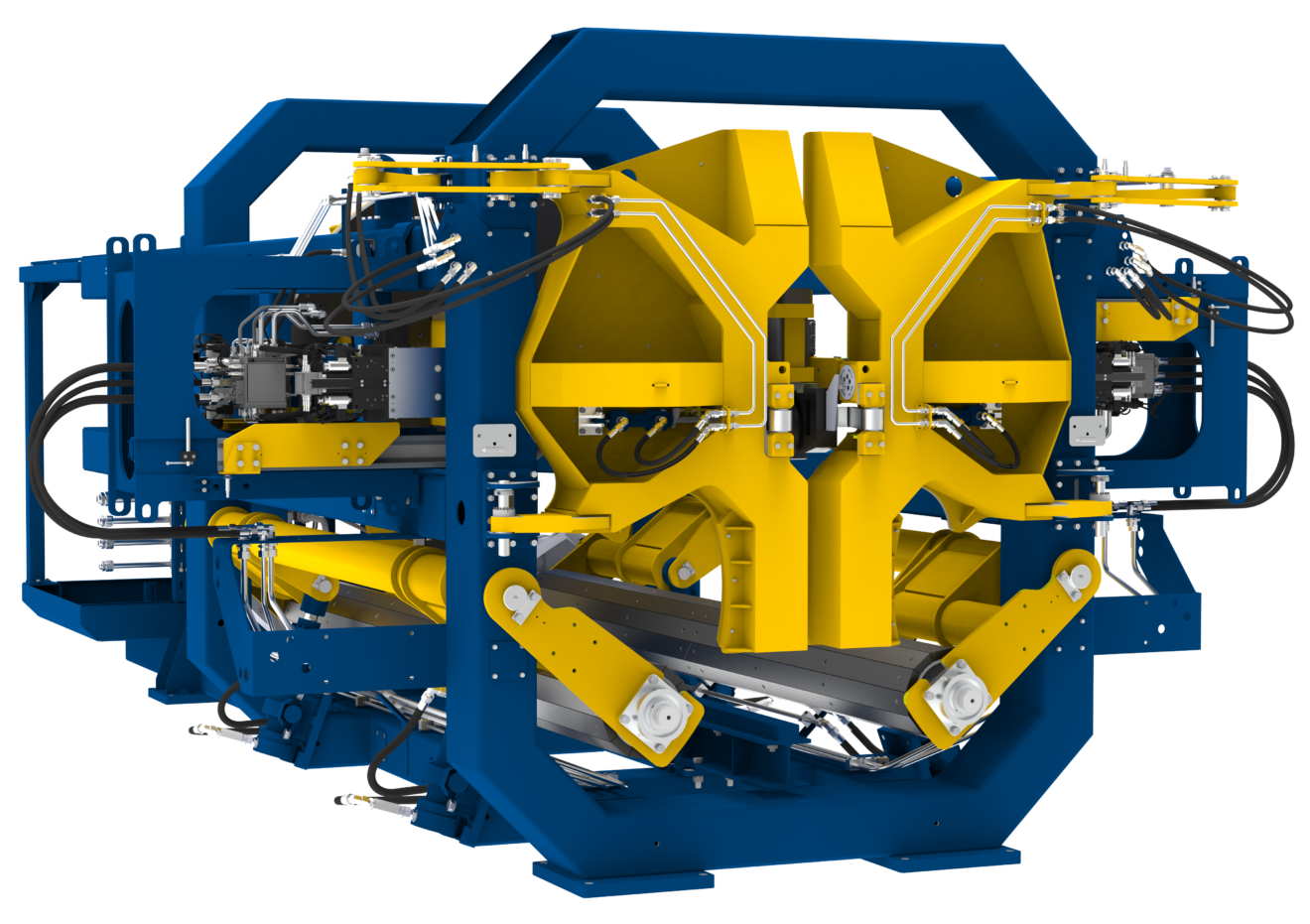

PCH-2

The PCH-2 Compactor is designed to be loaded

by forklift while maintaining efficient compacting

of wire rod coils. It can be adapted for a variety

of applications and equipped with wire binding or

strapping systems.

Quality off-line compacting

Building on proven Sund Birsta technology, the PCH-2 is an

easily integrated and low-maintenance horizontal compacting

station.

Long lifespan

The robust design and construction of the PCH-2 makes the machine reliable and durable.

Proven technology

Building on proven Sund Birsta technology, the PCH-2 is a reliable compactor in plants all around the world.

Scratch free process

The surface of the press plates can be exchanged to accomodate the sensitivity of the material being compacted.

Easy installation

The PCH-2 is delivered preassembled and tested. It is designed to easily integrate into any line in the wire rod mill.

Easy access to service

Protection covers are easy to dismount, giving good access to maintenance of the machine.

Variable pressure

The pressure of the PCH-2 Compactor can be adjusted steplessly between 25 and 100 kN.

Operation

The PCH-2 Compactor is designed to compact wire rod coils with a pressure of 25-100 kN. It consists of a movable press plate, a loading beam, rollers and two units for wire binding or strapping.

High availability and easy access for maintenance are features making the PCH-2 a cost-effective investment.

| Technical Specifications | PCH-2 |

|---|---|

| Lenght (mm) | 8500 |

| Height (mm) | 2950 |

| Width/depth (mm) | 4100* |

| Binding wire (mm) | 6.3-7.3 |

| Steel binding strap (mm) | 0.8 / 1.0 x 32 |

| Plastic binding strap (mm) | 0.8 / 1.35 x 32 |

| Max. coil weight (kg) | 4000 |

| Uncompressed coil length max (mm) | 2600 |

| Min. cycle time (s) | 90* |

| Net weight (kg) | 15000* |

| Press force (kN) | 25-100 |

| *Depends on machine size and coil size |