Wire

Ring Distributor

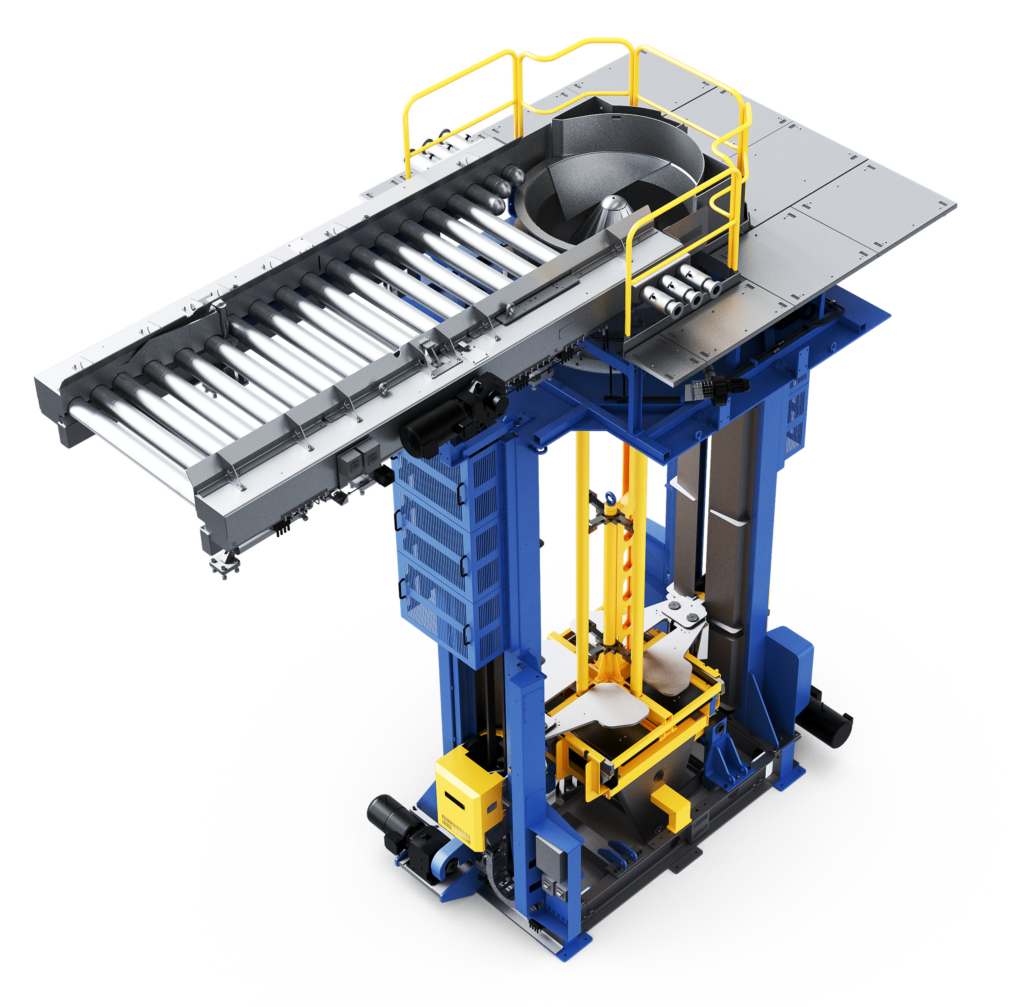

The ring distributor makes sure that the ring waps are optimally distributed into a coil, by using a rotating ring equipped with a wing to evenly displace/distribute the individual waps.

Efficient coil distribution

The ring distributor receives the coil waps from the Stellmor conveyor and distributes them down the pit tube in a rotating eccentric configuration where each individual wap is dropped a couple of degrees rotated from the previous wap, around the centre of the cone. This enables reduced coil height and gives better control of the coil shape as well as making the coil compressible in the Sund coil compactor. It also minimizes potential problems at later cooling, such as unevenly cooled coil waps.

Operation

The distributor is also equipped with iris fingers, where the coil waps are collected during the automatic change of pallet performed in the gap time between the billets. The iris fingers and the rotating ring are both electrically operated to reduce energy consumption to a minimum and to allow for best performance and operability.