Strip Coil

Strapping Machine

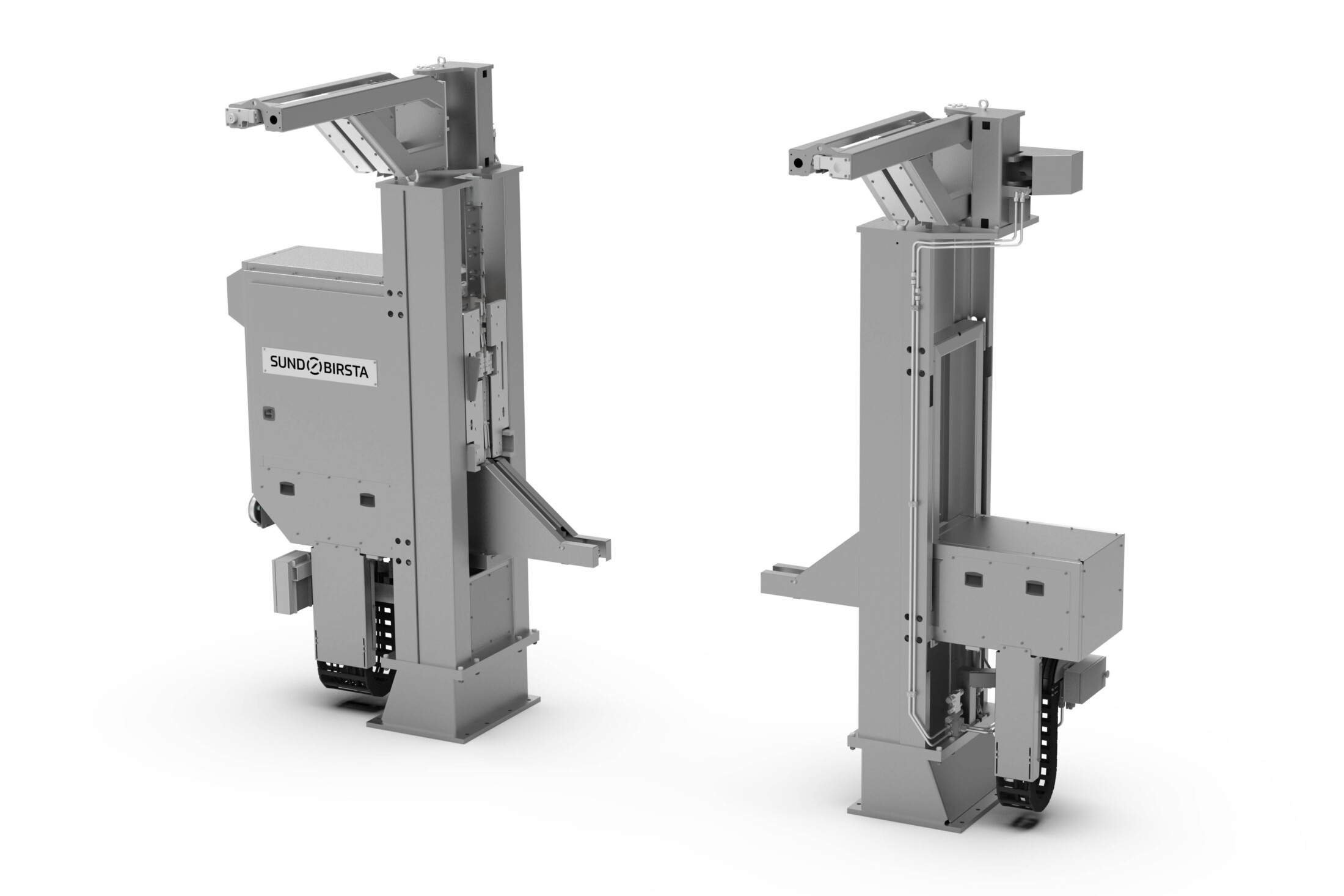

SMB-DC

The SMB-DC Strapping Machine features a heavy-duty design with a galvanized steel frame and stainless steel strap guides, making it ideal for the toughest environments near the downcoiler.

High-performing strapping in

the toughest environments

The machine is made to withstand the toughest conditions possible with extreme temperatures and high moisture levels.

Reliable

Durable materials and a simple yet innovative design makes this strapping machine very reliable and low maintenance.

Advanced sealing technology

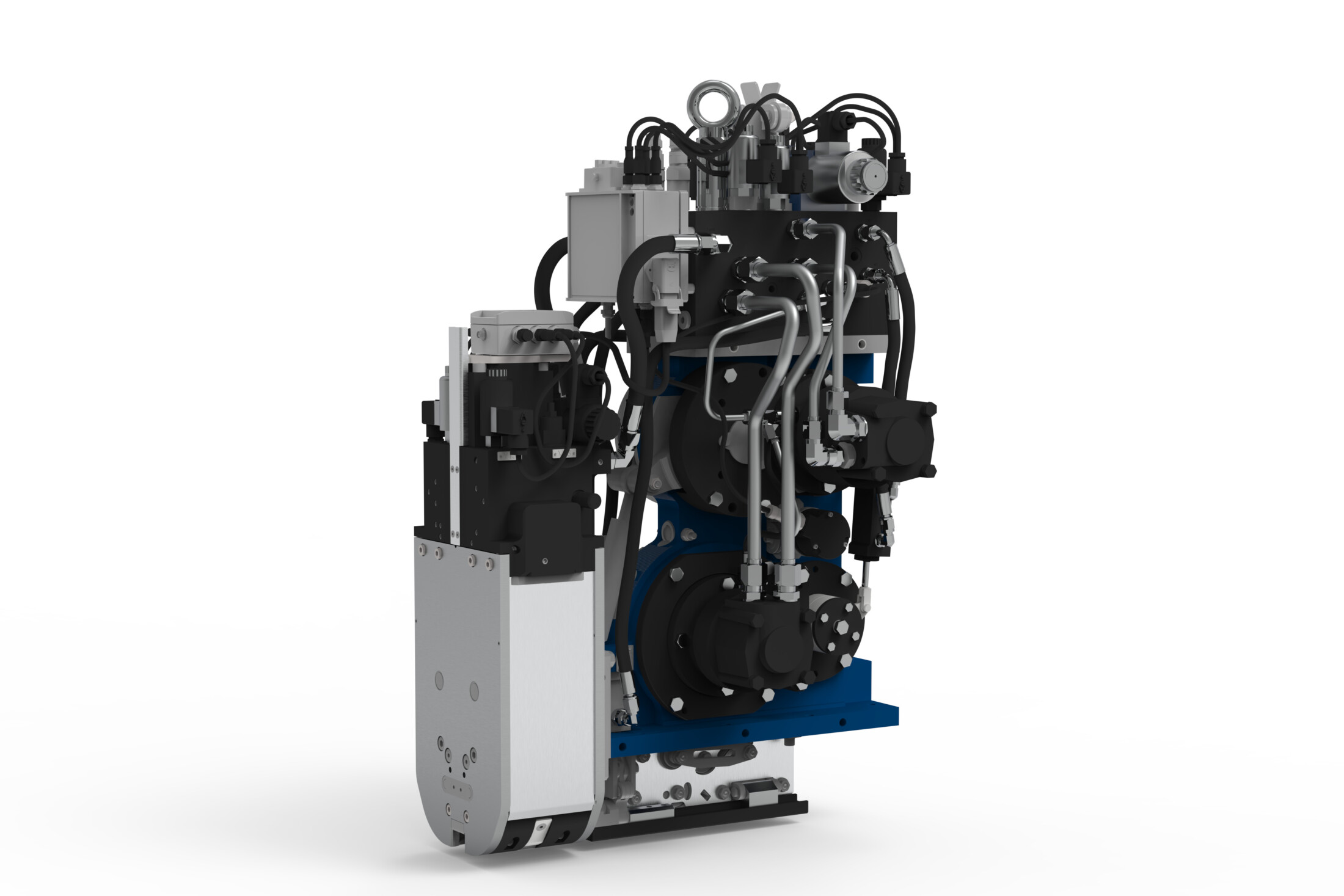

Equip the machine with the strapping head of your choice. Sund Birsta offers a wide selection of strapping heads capable of creating seal-less mechanical joints or welded joints.

Safety solutions

The SMB-DC is compatible with our IoT solution, enabling quick and solution-oriented remote support from Sund Birsta’s experienced engineers.

Support

Our dedicated Customer Service team ensures you receive the support you need, when you need it. Your production is our priority.

Remote service

The SMB-DC is compatible with our IoT solution, enabling quick and solution-oriented remote support from Sund Birsta’s experienced engineers.

Operation

When a strip coil arrives at the strapping position, the SMB-DC immediately positions itself and the strap guides align through slots in the conveyor. Strap is fed through the system and into the Strapping Unit. Once the strap is clamped, the movable strap guides retract, and the Feeding Unit pulls back a portion of the surplus strap while the Strapping Unit centers itself on the coil for optimal strapping conditions. The Strapping Unit then advances towards the coil while the remaining strap is retracted by the Feeding Unit. The Strapping Unit performs the seal, cuts the strap, and retracts to its initial position. If a second strap is necessary to mitigate the spring-back force, the machine can perform a second strap in the same position by repeating the cycle. Otherwise, the coil can be further conveyed.

SMB-DC

Features

Quick access frame

The SMB-DC can be equipped with a hydraulically openable upper frame to allow quick access when needed.

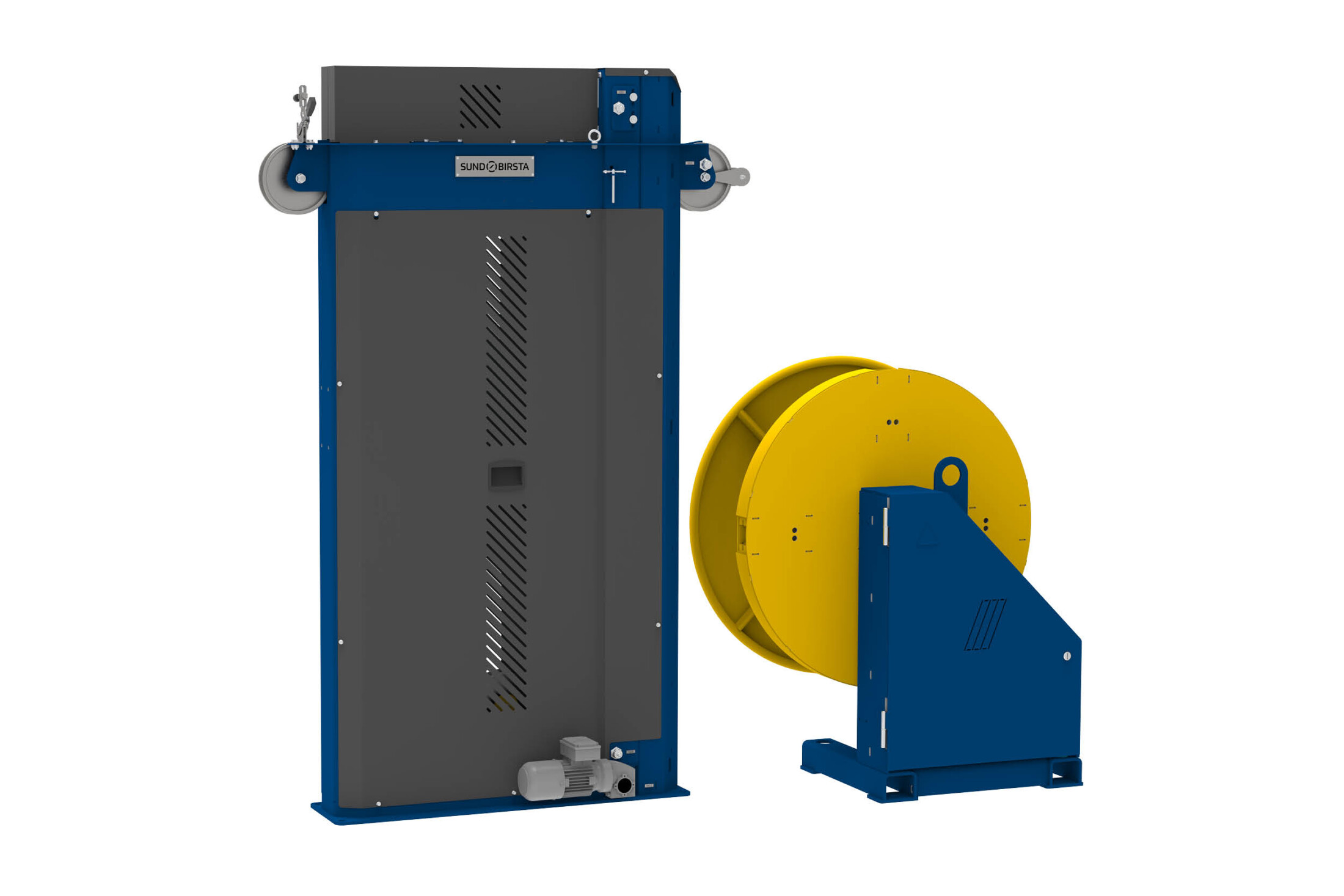

Next generation Accumulator

Faster, safer and more ergonomic. Discover our new accumulator and improve your productivity.

Click here to read more

SBHX5

- Sealless mechanical joint

- For 32 mm steel straps

- Retains 80% of the steel strap’s tensile strength

- Wear parts have a lifespan of up to 80,000 cycles

SBHRW

- 4-spot resistance welded joint

- For 32 mm steel straps

- Retains 90% of the steel strap’s tensile strenght

- Wear parts have a lifespan of up to 5,000 cycles

Our strapping heads can easily be fitted into existing strapping machines.