Strip Coil

Strapping Machine

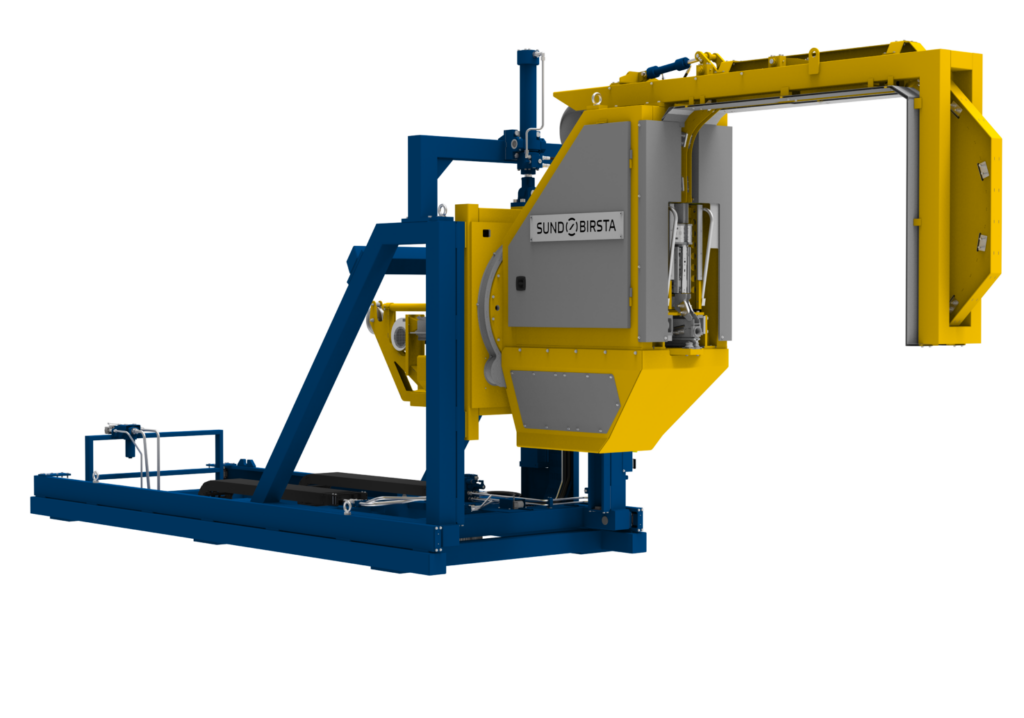

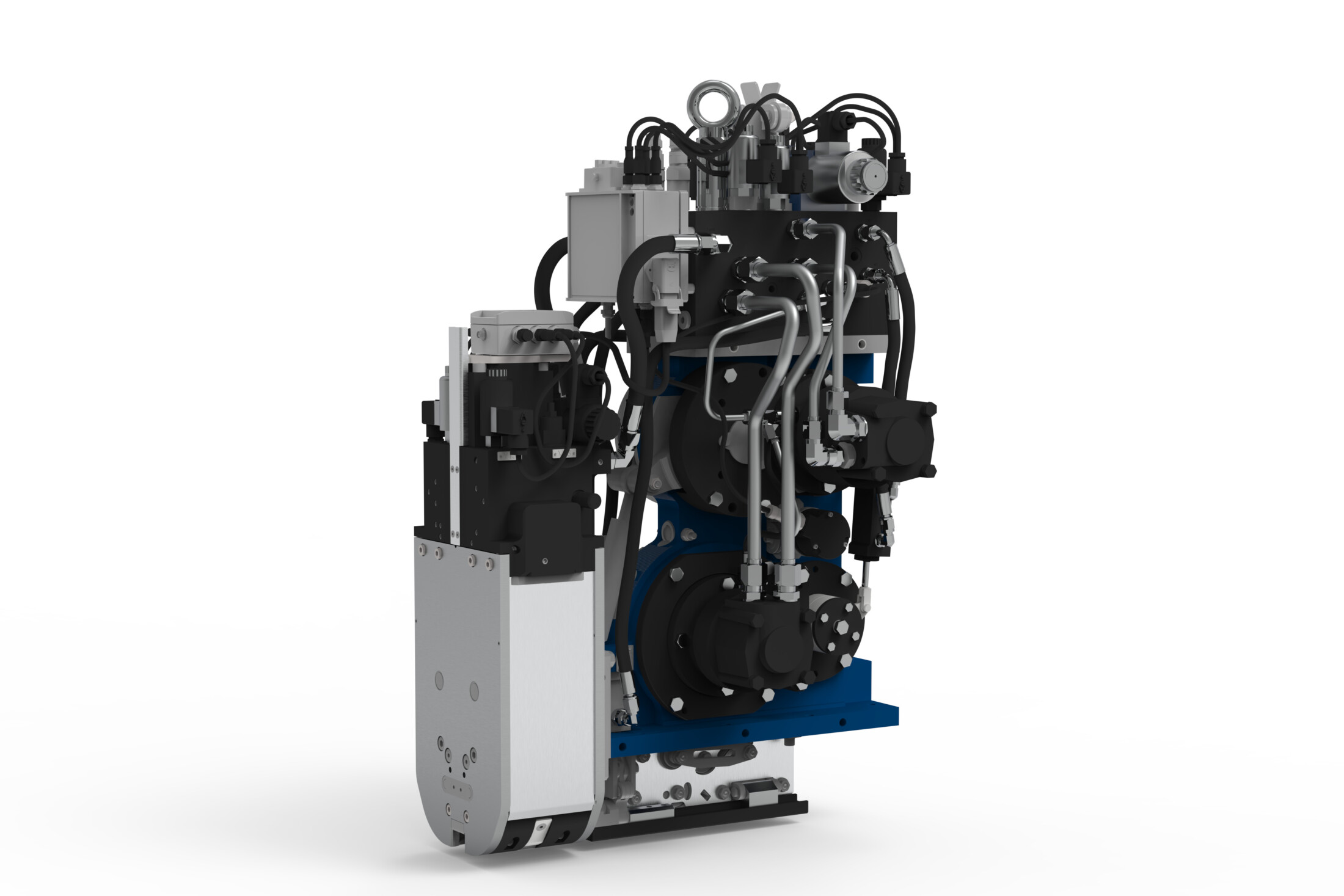

SMB-EV

The SMB-EV Strapping Machine applies straps radially through the inner diameter of the Coil. It is designed for the hot and demanding environments of Hot Strip Mills, and is compatible with any conveying system.

High-performing strapping in

your demanding environment

The machine is designed for the hot and demanding environments of Hot Strip Mills, and is compatible with any conveying system.

Flexibility

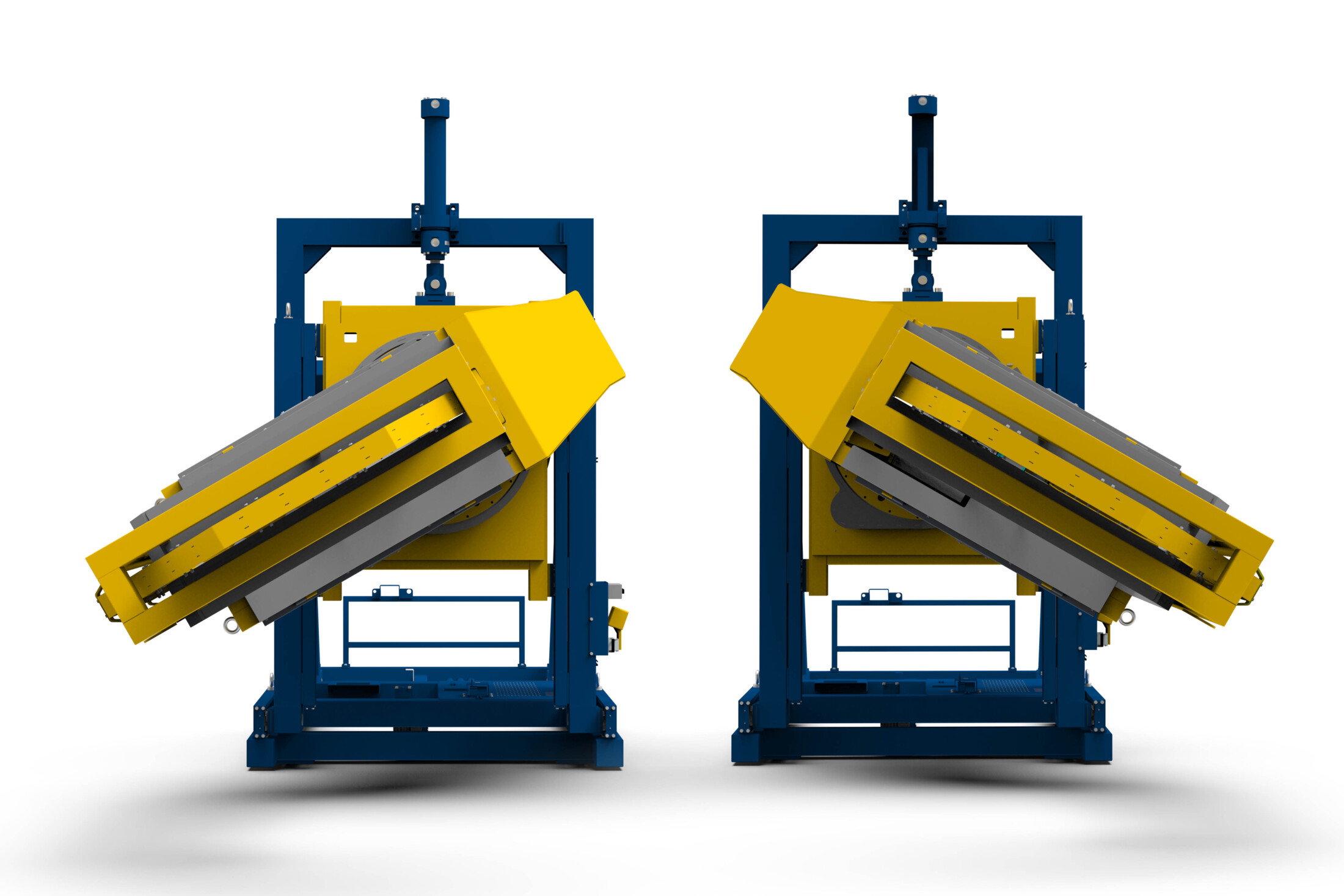

The SMB-EV can handle a wide set of coil dimensions and material temperatures, while enabling near endless numbers of strapping recipes thanks to the 240° rotation.

Continuous cooling

Strategically placed cooling fans and air channels allows continuous cooling of the machine during the whole strapping cycle.

Advanced sealing technology

Equip the machine with the strapping head of your choice. Sund Birsta offers a wide selection of strapping heads capable of creating seal-less mechanical joints or welded joints.

Safety solutions

Sund Birsta provides customized safety

solutions that comply with applicable standards and meet your specific requirements.

Support

Our dedicated Customer Service team ensures you receive the support you need, when you need it. Your production is our priority.

Remote service

The SMB-EV is compatible with our IoT solution, enabling quick and solution-oriented remote support from Sund Birsta’s experienced engineers.

Operation

When a strip coil arrives at the strapping position, the SMB-EV has already positioned itself vertically to align the moveable strap guide with the center of the coil eye. Upon receiving the start signal, the machine begins to rotate towards the first strapping position while the moveable strap guide runs forward to connect the strap guide system. When it has reached the strapping position and the strap guide system is connected, the strap is fed through the system and into the Strapping Unit. The strap is then clamped, and the Feeding Unit retracts surplus strap while the Strapping Unit and the Strap Support moves towards the Coil. The Strapping Unit performs the seal, cuts the strap and returns to its retracted initial position. The strap guides remain connected and rotates towards the next strapping position while simultaneously feeding new strap through the strap guide system. Upon reaching the new strapping position, it is ready to strap and the cycle repeats. When the required number of straps have been applied, the moveable strap guide is drawn back and the machine rotates to its upright initial position to make way for the conveyor and Coil.

SMB-EV

Features

240° rotation

The SMB-EV can rotate 240° and

apply straps anywhere along the arc.

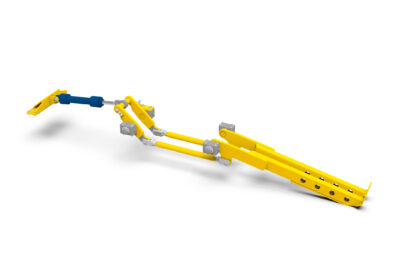

Strap support

Equip the machine with a Strap Support and reach even higher strapping tightness.

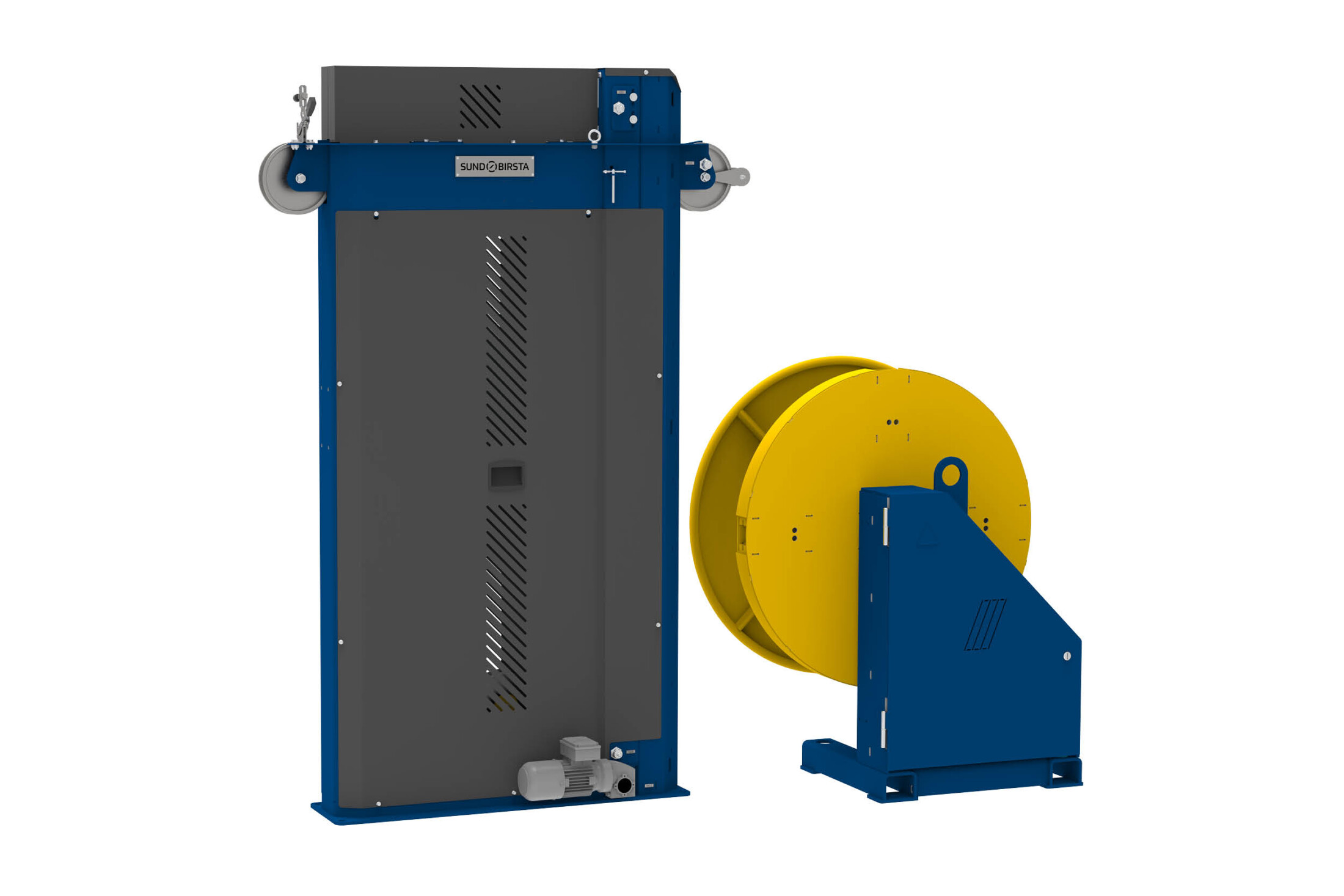

Next generation Accumulator

Faster, safer and more ergonomic. Discover our new accumulator and improve your productivity.

Click here to read more

SBHX5

- Sealless mechanical joint

- For 32 mm steel straps

- Retains 80% of the steel strap’s tensile strength

- Wear parts have a lifespan of up to 80,000 cycles

SBHRW

- 4-spot resistance welded joint

- For 32 mm steel straps

- Retains 90% of the steel strap’s tensile strenght

- Wear parts have a lifespan of up to 5,000 cycles

Our strapping heads can easily be fitted into existing strapping machines.