Strip Coil

Strapping Machine

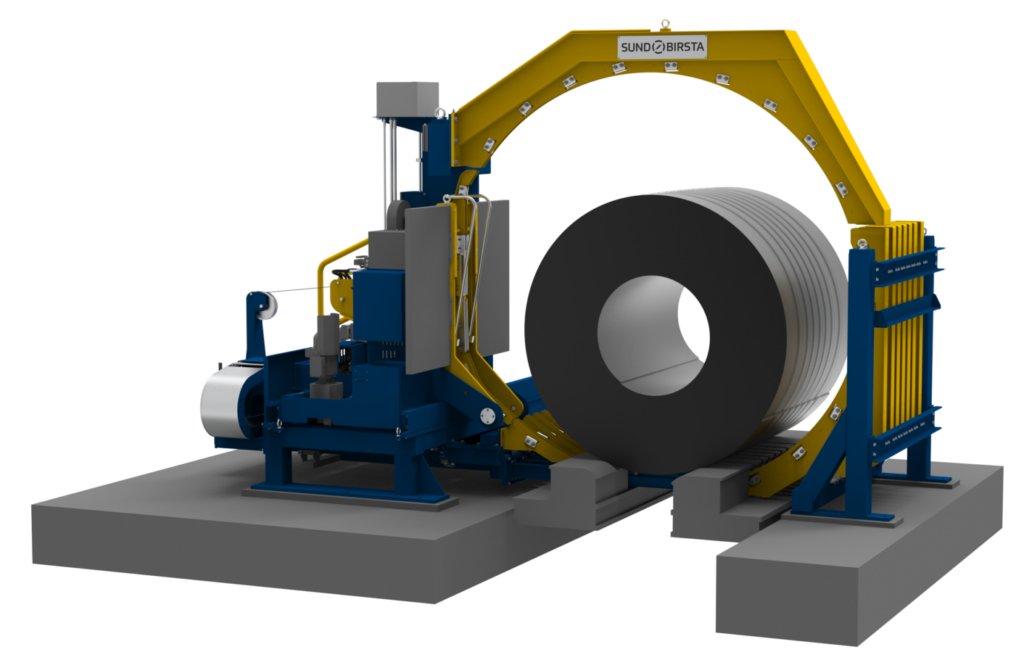

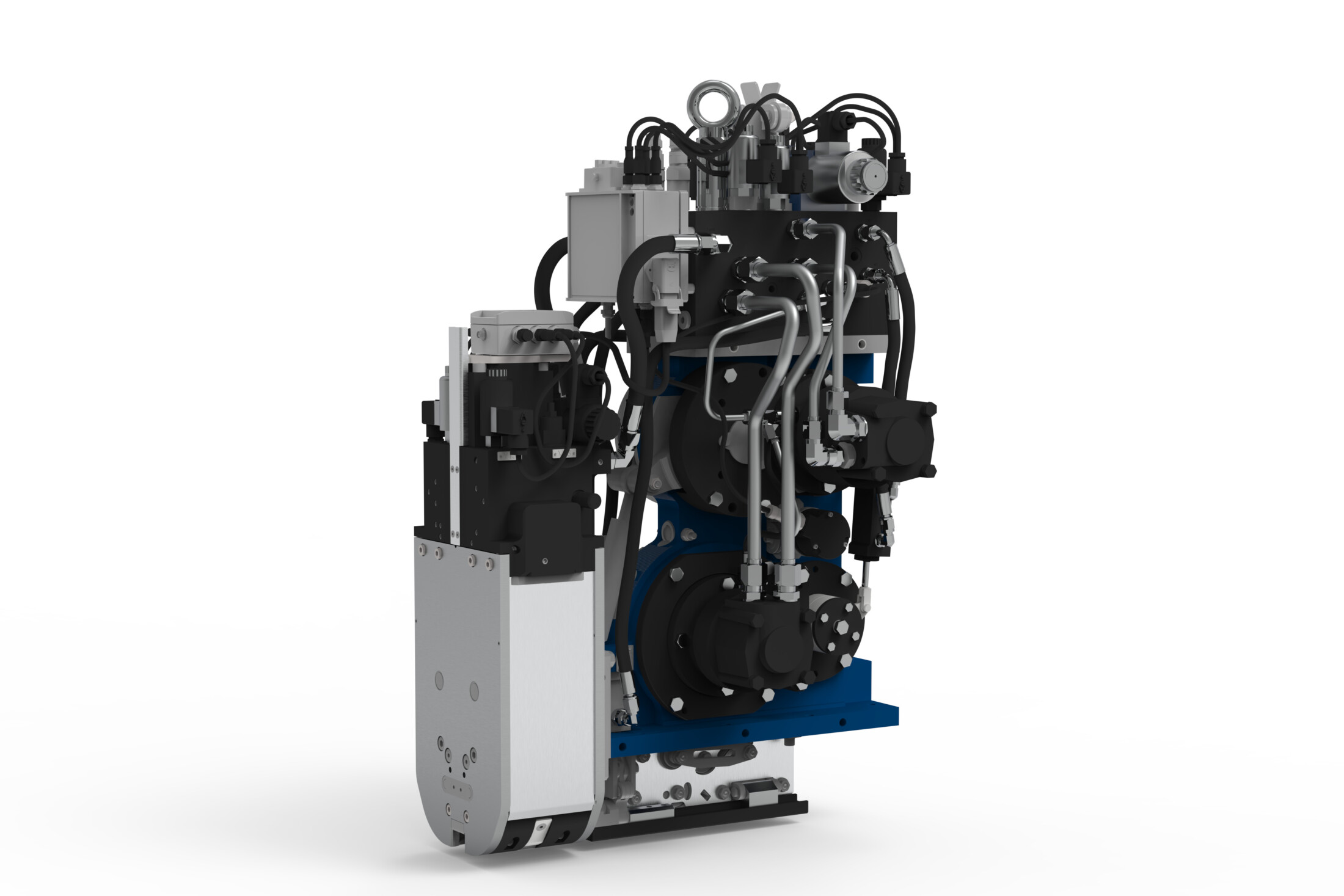

SMB-M

The SMB-M is designed for strapping strip coils. With multiple configurations available it is a highly versatile machine. Ready to handle your production.

Our excellent performance in your challenging environments

The SMB-M is designed for strapping strip coils in the

most demanding environments, efficiently and reliably.

Engineered to last

With durability in mind, this strapping

machine has been designed to withstand harsh industrial environments and remain durable throughout it’s lifetime.

Versatile

The machine can be adapted to fit your needs in terms of coil sizes, cycle times, sealing technology, strapping recipes and more.

Advanced sealing technology

Equip the machine with the strapping head of your choice. Sund Birsta offers a wide selection of strapping heads capable of creating sealless mechanical joints or welded joints.

Safety solutions

Sund Birsta provides customized

safety solutions that comply with applicable standards and meet your specific requirements.

Support

Our dedicated Customer Service team ensures you receive the support you need, when you need it. Your production is our priority.

Remote service

The SMB-M is compatible with our IoT solution, enabling quick and solution-oriented remote support from Sund Birsta’s experienced engineers.

Operation

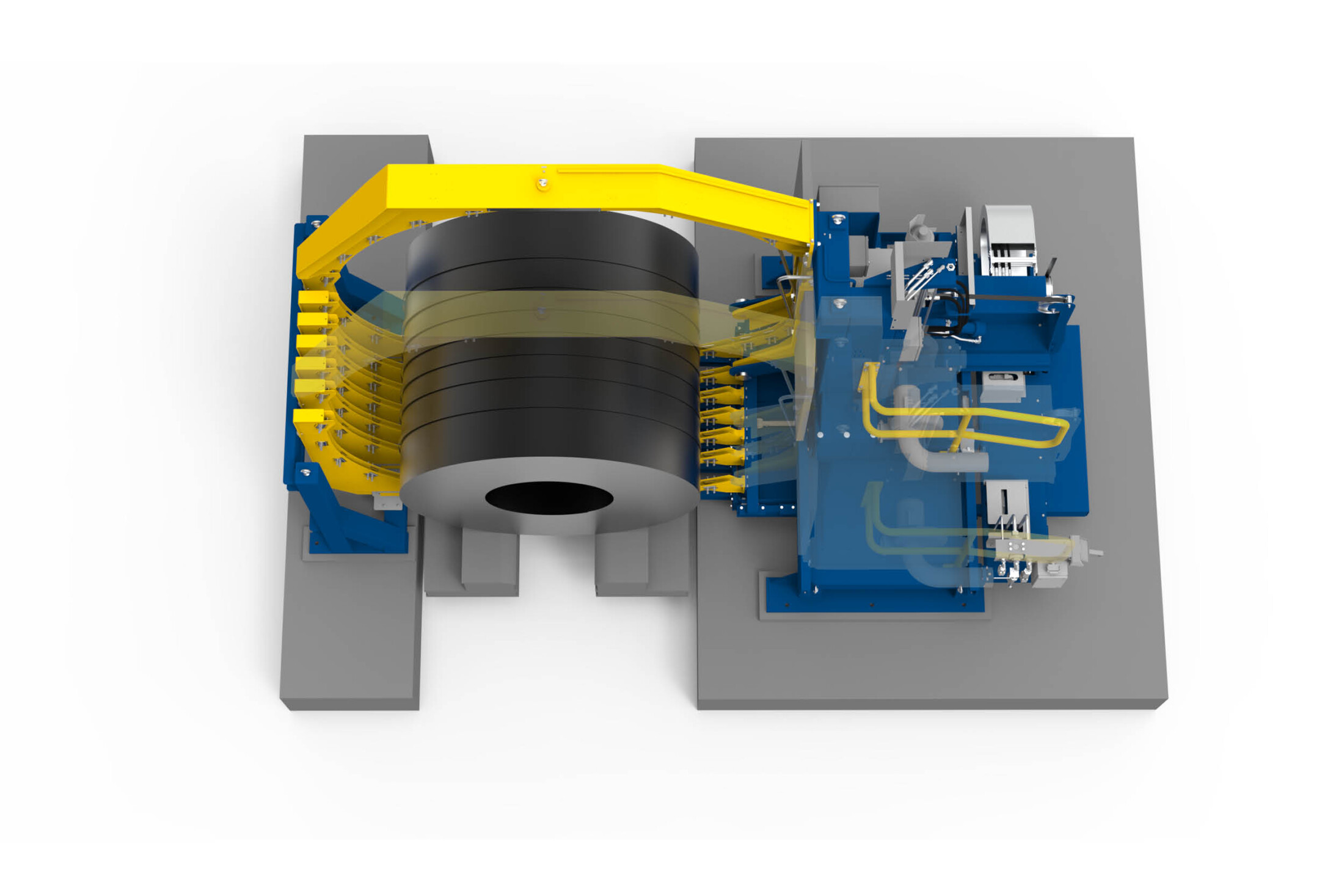

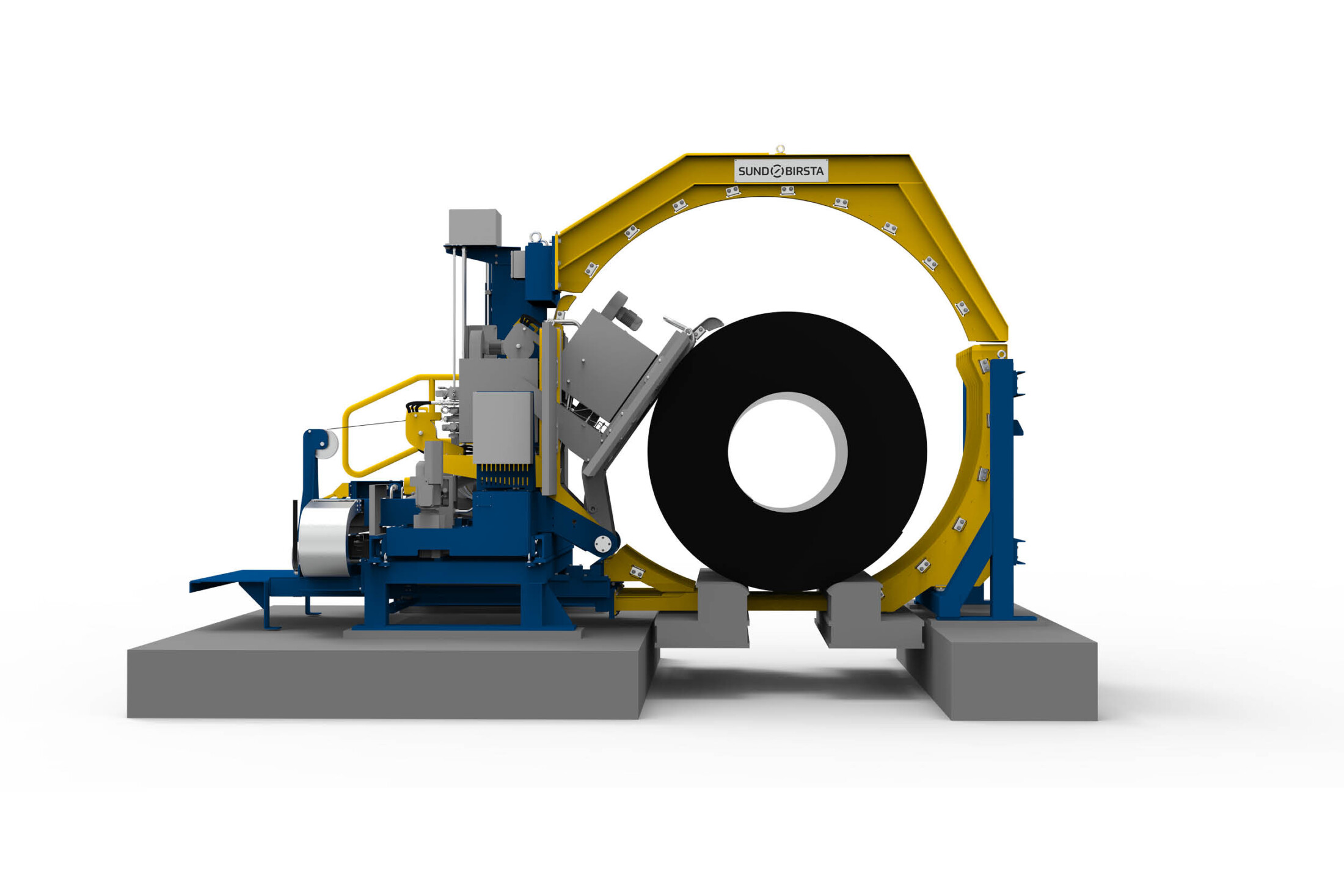

When a Strip Coil arrives at the strapping position, the strap is already pre-fed in the strap guide system. As the Conveyor is lowered, the lower strap guides moves forward, connecting the strap guide system. The strap is then fully fed through the system, the Strapping Unit is tilted forward towards the coil and the strap is stretched around it. The Strapping Unit performs the seal, cuts the strap and returns to its upright, initial position. The Strapping Machine moves horizontally to the next strapping position, and the sequence reiterates. When all required straps have been made, the lower strap guides retracts, and the Coil can be further conveyed.

SMB-M

Features

Adjustable to your strapping needs

The SMB-M can be equipped with a customizable range of strap guides to fit your specific strapping needs.

Handles a large variety of coil sizes

A pivoting sealing unit ensures optimal strapping conditions are received, no matter the coil size.

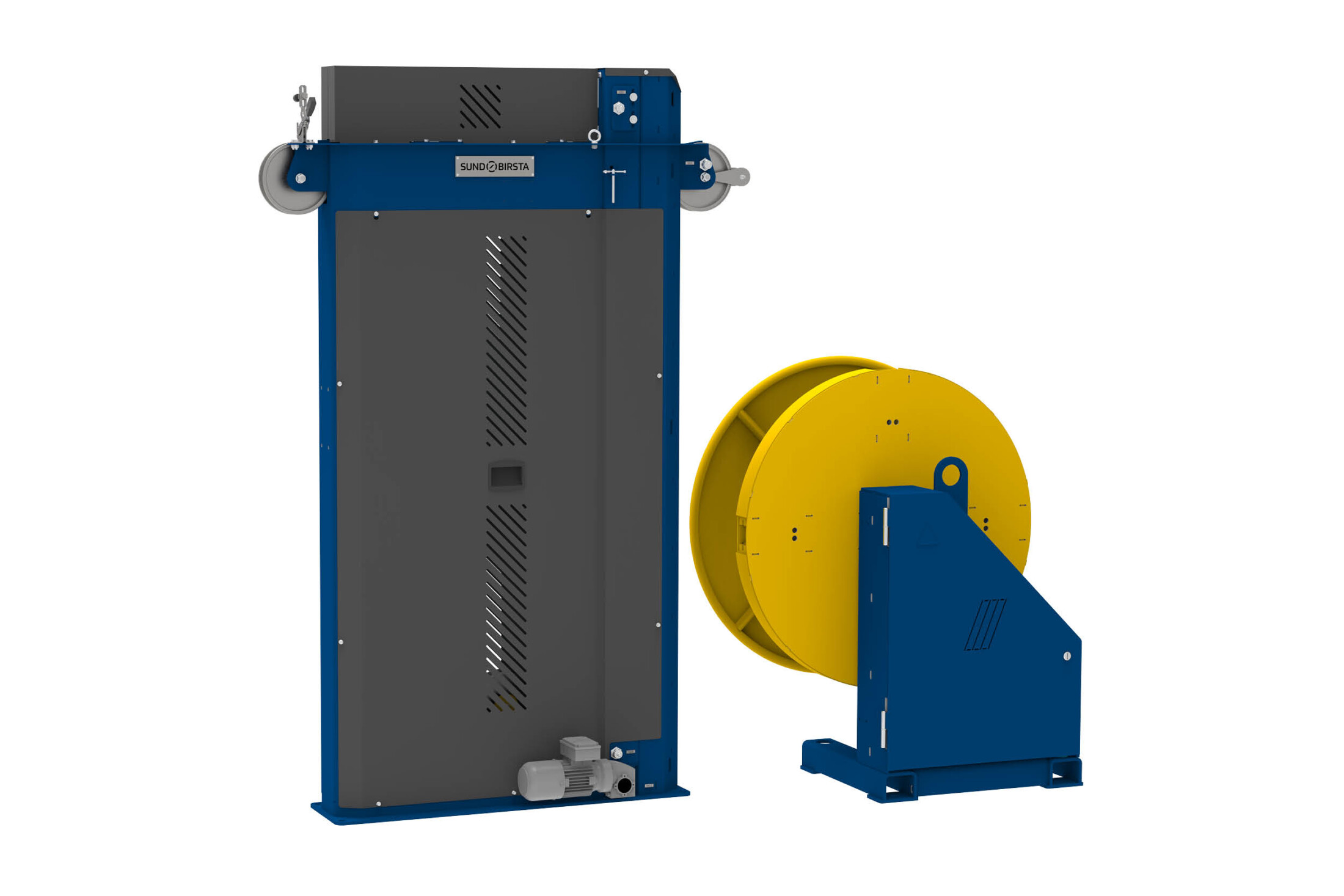

Next generation Accumulator

Faster, safer and more ergonomic. Discover our new accumulator and improve your productivity.

Click here to read more

| Technical Specification | SMB-M |

|---|---|

| Material temperatures | Up to 850 °C |

| Sealing technology | Mechanical or weld |

| Strap width | 32 mm |

| Coil sizes | Customizable |

| IoT compatible | Yes |

SMB-M

Strapping heads

SBHX5

- Sealless mechanical joint

- For 32 mm steel straps

- Retains 80% of the steel strap’s tensile strength

- Wear parts have a lifespan of up to 80,000 cycles

SBHXL5

- Sealless mechanical joint

- For 50.8 mm steel straps

- Retains 80% of the steel strap’s tensile strength

- Wear parts have a lifespan of up to 80,000 cycles

SBHRW

- 4-spot resistance welded joint

- For 32 mm steel straps

- Retains 90% of the steel strap’s tensile strenght

- Wear parts have a lifespan of up to 5,000 cycles

Our strapping heads can easily be fitted into existing strapping machines.