Wire

Coil handling system

SUNDCO Concept

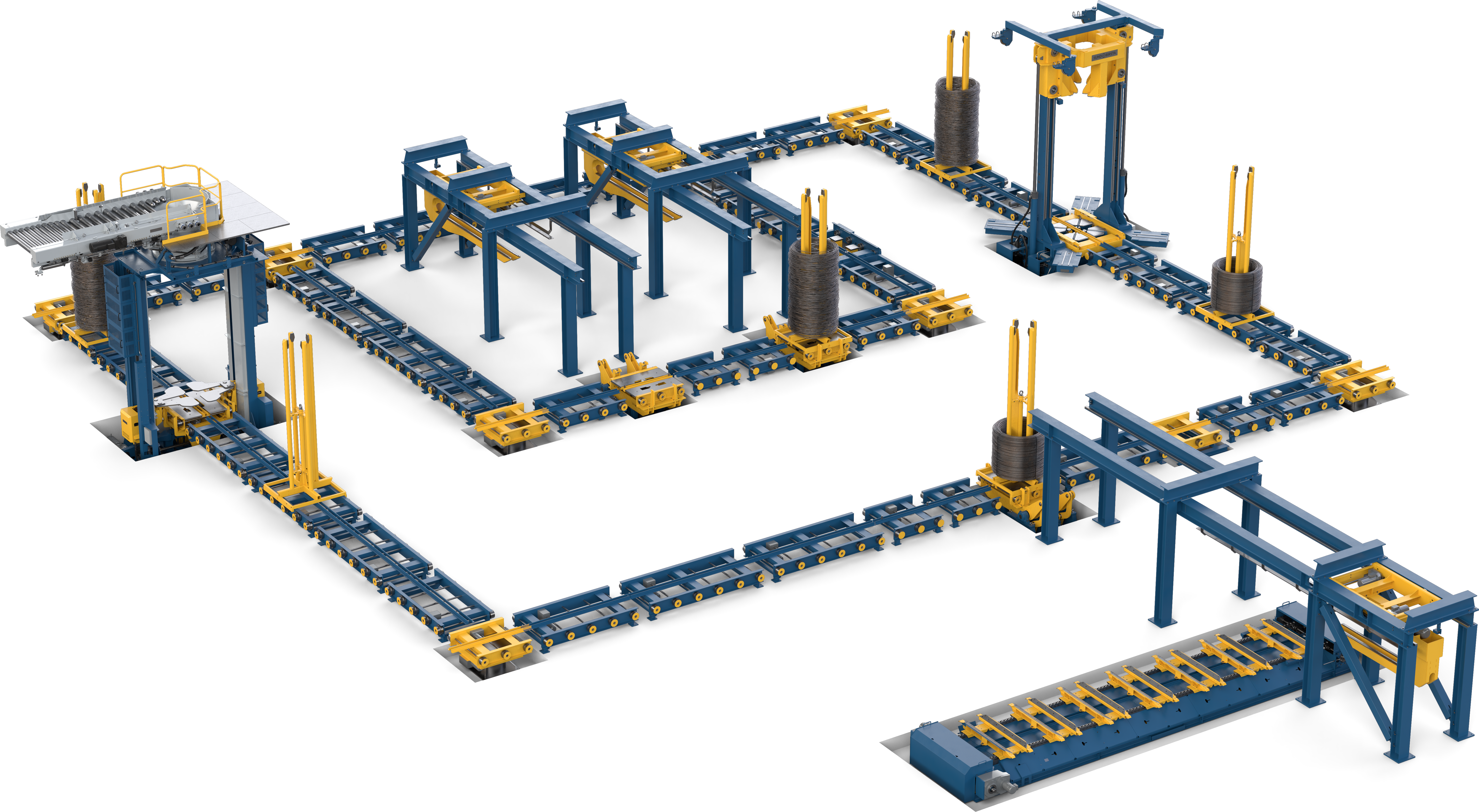

The SUNDCO-V/H has a modern, space-saving design combining the advantages of vertical and horizontal handling systems, making it a powerful and practical solution for trimming of coils.

Smooth and gentle handling for coils

Building on proven Sund Birsta technology, the SUNDCO Concept has developed into a state of the art handling system for coils.

Combining the best of

vertical and horizontal coil handling

The hook of the SUNDCO-V/H can be oriented in any direction to accommodate the various working stations, while maintaining excellent stability. The system uses frequency drives for optimized positioning and speed control, with minimum power consumption. The SUNDCO handling system is designed for smooth and gentle handling of coils, transporting them to different working stations in the mill. The heavy yet simple construction, devoid of sensitive components and utilizing a quite belt drive, makes the system very low maintenance. The SUNDCO handling system is available for both vertical and horizontal handling of coils, or a combination of the two.

The system is fully automatic, but parts can be operated manually. The pallet line is designed to accommodate the mill layout as per capacity, number of working stations, coil weight and buffer demand.

Optimized Safety System

Safety is an important issue for Sund Birsta. Our machines and handling equipment are designed to meet high demands on macine safety. Depending on your requirements, we offer an optimized safety system.

Electrical Control System – Tracking

The complete handling system, from loading of an uncompacted coil to unloading of compacted and tied/strapped coils, is fully automatic PLC controlled. Tracking of the coils is based on hook identification readers interconnected with the mill computer system.

A high-quality and cost-efficient

vertical coil handling system

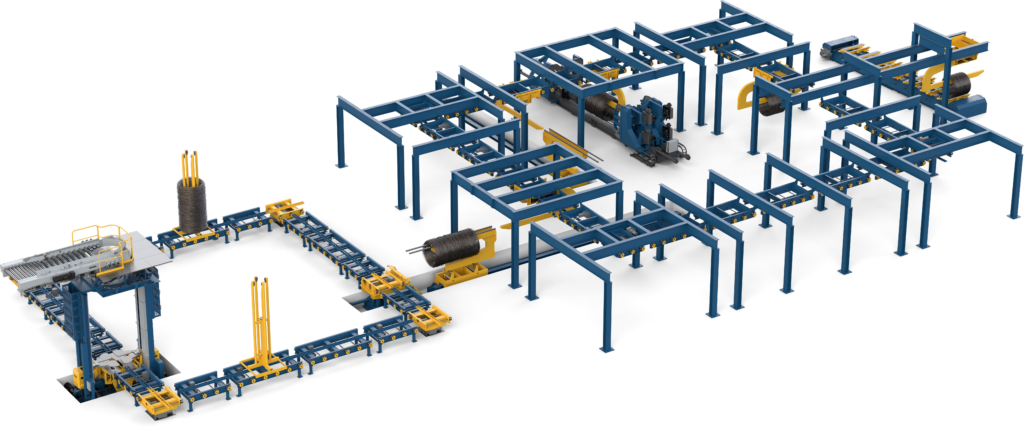

SUNDCO-V Wire Coil Handling System

The SUNDCO-V has a modern, space-saving design using very little floor space, and a cooling buffer area can be created efficiently. The system uses frequency drives for optimized positioning and speed control, with minimum power consumption.

SUNDCO Concept

Upgrades

Automatic Labelling Station

Designed for high availability, great accuracy and low maintenance, the automatic labelling station assures a consistent high quality. It has an integrated coil inspection system, with a camera that scans possible positions for tagging and then chooses the best one for fast tagging of the coil.

Workshop Service

Each machine has its own unique service demands, and we also understand that each of our customers have their own individual requirements. Our service reflect that, and we deliver the best maintenance available for your Sund Birsta system. Contact us with your specific service and inspection needs.