Bar & section

Automatic Labelling Station

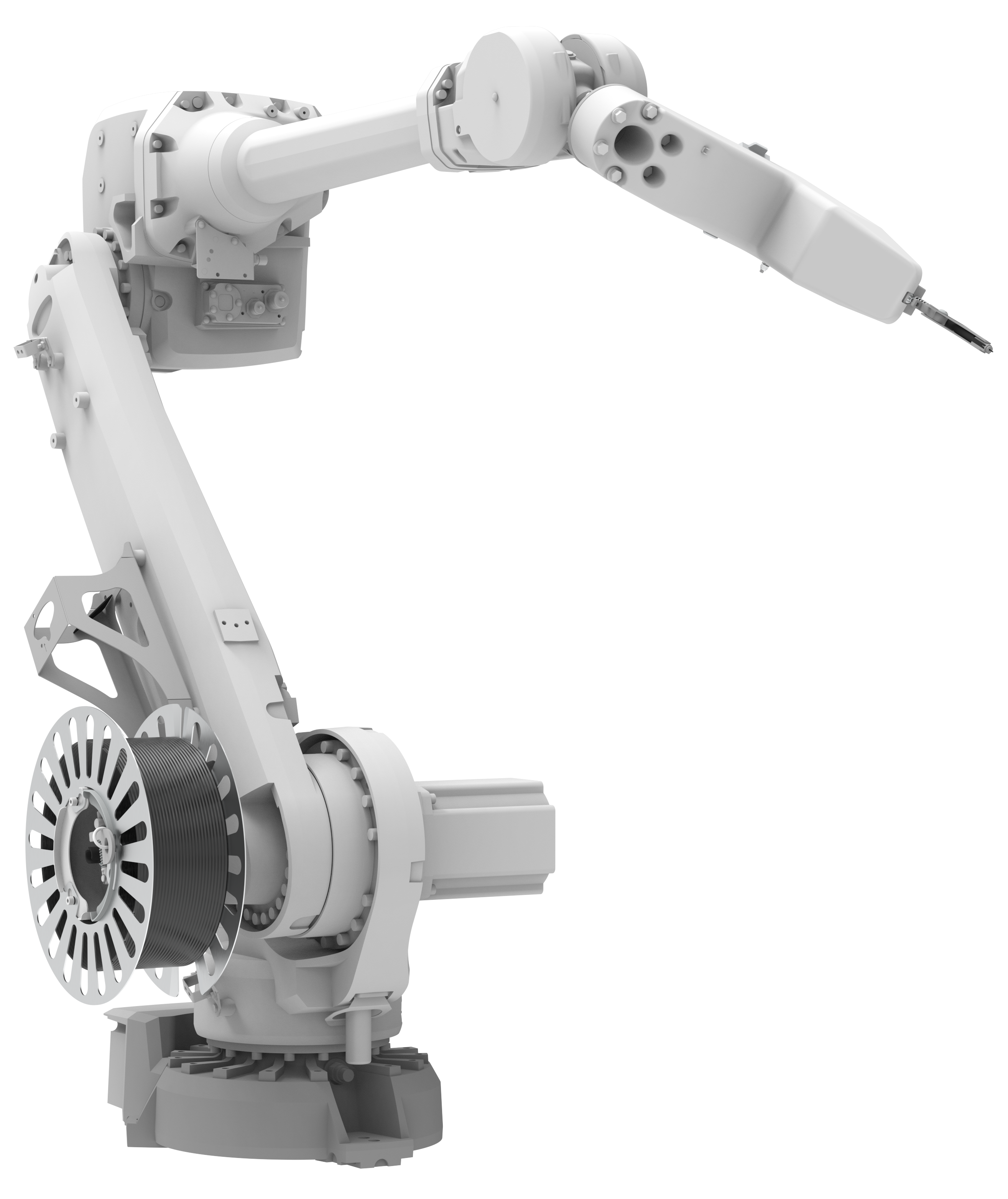

The tag marker for long products is designed to be reliable and flexible to the customer needs.

Maintenance and upgrades

As the system is delivered with a service package, wear, spare parts, service and design updates are included. This sets low cost of ownership and assure a high accuracy for the function. Key components are easy and fast to swap, and then to be sent to Nearest Sund Birsta service workshop.

Operation

The system can be controlled via HMI or connected to local/customers level2 system. The operator can

adjust all flexible parameters easily. Options as an example can be how many tags attached to one

product, position where to attach the tag and redundant position etc. Production data and performance

are presented on HMI.

Label attachment

The label attachments shape is flexible. This allows the system to adapt to our

customers needs and various product range. This to ensure the reliability and secure that the tag is

attached through the complete chain of delivery.

Remote support

With remote connection our full

know-how can be utilized as a support.

Predictive maintenance

Utilize data from presence to learn when your system needs service and maintenance, to prevent any loss of production and non-planned stops.